Many types of surfaces are submitted to the laboratory for latent print processing. With different surface types, there are different techniques that can be used to develop latent prints.

Non-porous Surfaces

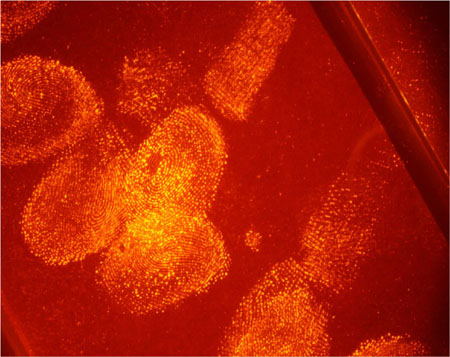

These are mainly smooth surfaces of which the latent print resides on the surface. Examples of non-porous surfaces include glass, plastics, metals, and varnished wood. Latent prints on non-porous surfaces tend to be fragile, so they must be preserved as soon as possible. The primary technique is to expose the non-porous surface to superglue fumes (cyanoacrylate ester). Superglue reacts with moisture present in the latent print, converting the latent print into a hard plastic, and bonds it to the surface.

These are mainly smooth surfaces of which the latent print resides on the surface. Examples of non-porous surfaces include glass, plastics, metals, and varnished wood. Latent prints on non-porous surfaces tend to be fragile, so they must be preserved as soon as possible. The primary technique is to expose the non-porous surface to superglue fumes (cyanoacrylate ester). Superglue reacts with moisture present in the latent print, converting the latent print into a hard plastic, and bonds it to the surface.

The surface can then be treated with a fluorescent dye stain and examined under a laser. The dye stain adheres favorably to the superglue residue, so any latent prints preserved by superglue fuming process will fluoresce under the laser.

Porous Surfaces

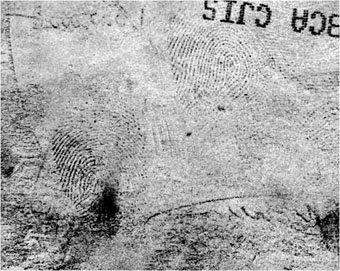

These are surfaces of which the latent print is absorbed into the material. Examples include paper, cardboard, and untreated woods. Various chemical treatments are used to develop latent prints in porous materials. The chemicals target certain components present in the latent print residue, reacting as a color change, making the latent print visible. DFO and Indanedione are two chemicals that target particular groups of amino acids that are present in latent print residue. The surface is treated with these chemicals and examined under a laser. If latent prints are present, they will fluoresce upon exposure to the laser.

These are surfaces of which the latent print is absorbed into the material. Examples include paper, cardboard, and untreated woods. Various chemical treatments are used to develop latent prints in porous materials. The chemicals target certain components present in the latent print residue, reacting as a color change, making the latent print visible. DFO and Indanedione are two chemicals that target particular groups of amino acids that are present in latent print residue. The surface is treated with these chemicals and examined under a laser. If latent prints are present, they will fluoresce upon exposure to the laser.

Ninhydrin also reacts with amino acids in latent print residue. An advantage of ninhydrin is that a laser is not needed. If latent prints are present, the ninhydrin will turn them purple.

Physical Developer reacts with fatty acids that are sometimes present in latent print residue, turning them black. Because fatty acids are insoluble in water, Physical Developer is useful on porous items that have been wet.

Physical Developer reacts with fatty acids that are sometimes present in latent print residue, turning them black. Because fatty acids are insoluble in water, Physical Developer is useful on porous items that have been wet.

Other Surfaces

The laboratory occasionally receives items with surfaces that don’t necessarily fall into the category of either porous or non-porous. Some examples of other surfaces and the preferred processing technique include:

Adhesive tape – Sticky-side powder

Waxy surfaces – Sudan Black

Glossy cardboard – Superglue fuming and fingerprint powder

Surfaces contaminated with blood – Amido Black